Rotary valve

Top brand rotary valve “AISHIN INDUSTIAL”

A rotary valve is one of the most important equipment for airlocks in the discharging and quantitative supply of powder and granules from a hopper/tank and pneumatic transportation. AISHIN INDUSTIAL has standardized rotary valves by application based on its long years of experience and achievements in Japan to meet your needs. AISHIN INDUSTIAL (THAILAND) is providing such equipment in the ASEAN region.

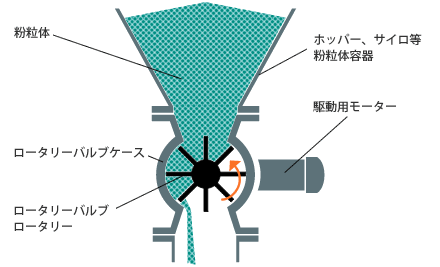

What is a rotary valve?

It is a mechanism in which a rotor that is driven by a motor is inserted into a horizontal cylindrical case, and powder particles that fill the rotor are moved from the upper part to the lower part by rotation and discharge/supply by gravity. The flow and stopping of the powder particles can be controlled by turning on/off the rotation. By combining the rotor with a variable speed motor, it is also possible to control the feed speed of powder particles.

The size of the rotary valve is determined by the required discharge capacity. In addition, as there are various types of powder and granules to be handled, the optimal one can be selected from combination of all specifications such as material, rotor shape, and various options.

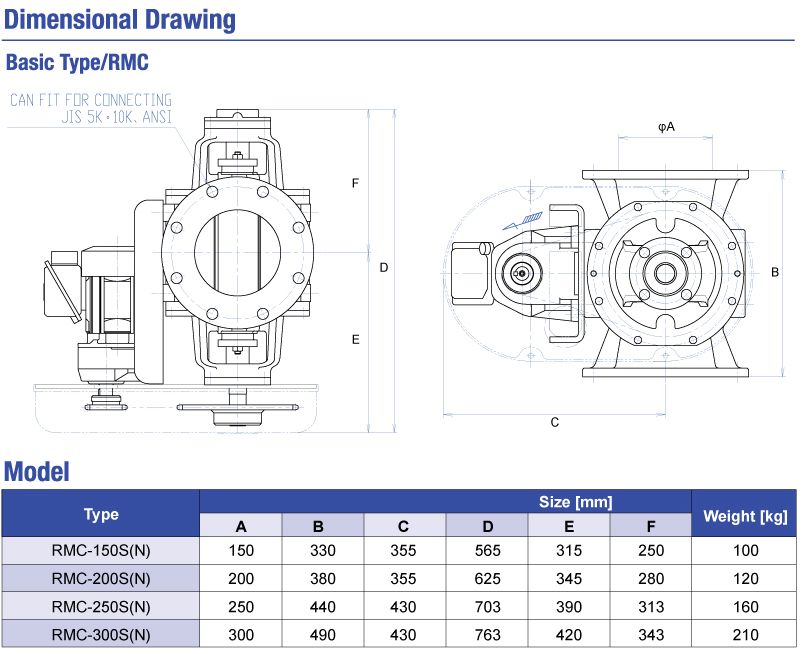

◆Standard drawings and equipment dimensions

◆Standard specifications

Materials for powder contact parts: SCS13/S30408/ASTM304 or FDC450/SS400

Temperature condition: -10 to less than 110℃

Pressure: less than ±30kPa

*We will select and propose a specification according to the customer’s usage conditions.

*In, addition, please check the warranty conditions.

*Please contact us for other sizes.

◆Various options

Material

- Powder contact part

Aluminum/Hastelloy/Inconel/Titanium, etc.

*Standard: FC200/FCD450/SS400 equivalent, SCS13/SUS304 equivalent (S30408/ASTM304) - rotor

Aluminum/Hastelloy/Inconel/Titanium/Welhard 400 etc.

*Standard: FC200/FCD450/SS400 equivalent, SCS13/SUS304 equivalent (S30408/ASTM304)

Inner surface finish

- Case powder contact part: Buffing #300,400/ Electropolishing /Teflon coating, etc.

*Standard: Both steel and stainless steel are machined on the inner surface of the cylinder, and can support a rough-buffing on the throat part and a buffing on the outer surface of the case.

- Rotor: Buffing #300,400/ Electropolishing /Teflon coating, etc.

*Standard: Both iron and stainless steel are used as is.

finish for wear protection

- Inner surface of the case: hard chrome plating/tungsten carbide spraying/ceramic spraying/nitriding treatment/lattice-like buildup for seal parts, etc.

*Selection: Only the inner surface of the cylindrical part (sliding part)/the entire surface including the inner surface of the throat part - Rotor: Cutting edge hardened buildup (HF-350 equivalent)/cutting edge Stellite buildup/full surface nitriding treatment, etc.

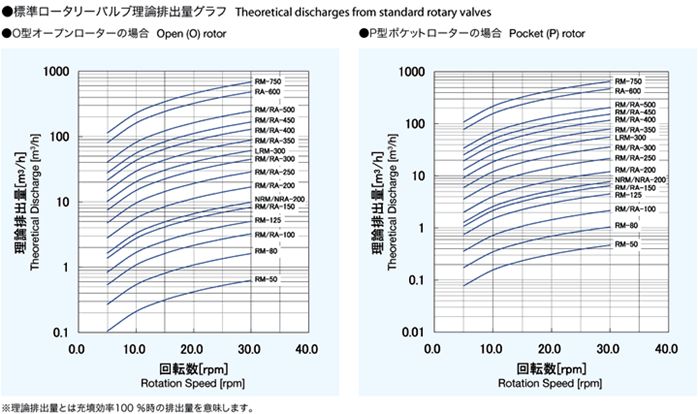

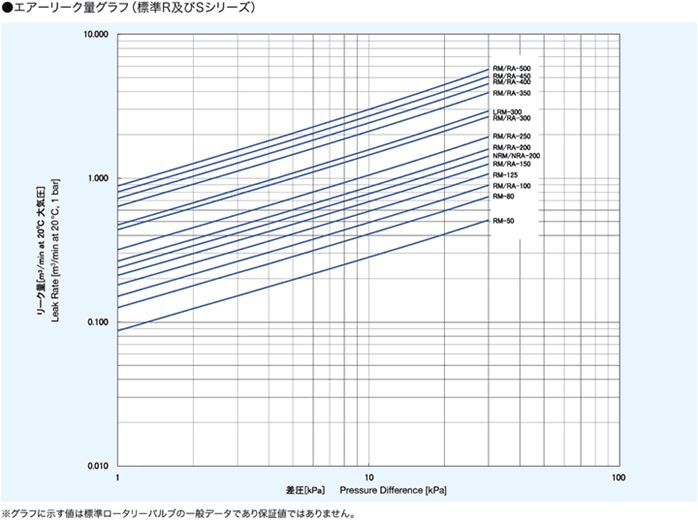

◆Technical data

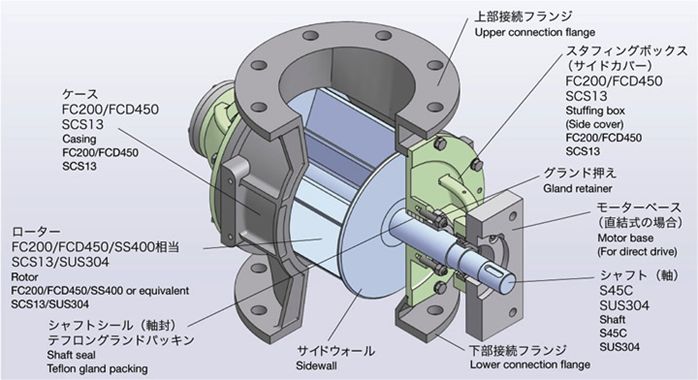

Rotary valve structure

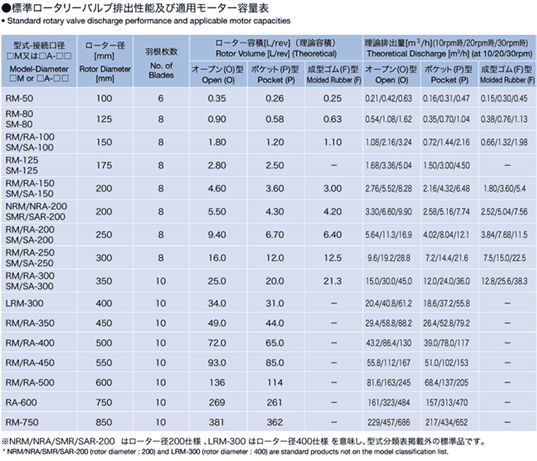

Discharge performance

Inquiry about rotary valve

In the case of not specifying a model, we will make a selection for you. Please let us know the following information.

- Applications: pneumatic transportation (pressure feeding/suction)/quantitative supply/discharging of dust collectors, etc.

- Processing amount (discharging amount): volume per unit time [m3/h]/mass per unit time [kg/h], etc.

- Powder particle name, bulk density, particle size (particle diameter), temperature, water content, angle of repose, wear, adhesion, etc.

- Usage conditions: pressures and temperatures at the top and bottom

- Connection: desired connection diameter, round flange JIS5K/JIS10K, square flange, etc.

- Model classification: general/sanitary specifications, etc.

- Material: iron/stainless steel for powder contact parts/special material, etc.

- Drive: directly connected to motor/chain, sprocket, etc.

- Others: shaft sealings, prohibited materials, surface treatments such as buffs, hard facing, dimensional constraints, etc.

- Painting specifications: paint, coating method, painting color, etc.

- Motor specifications: power supply voltage, frequency, indoor/outdoor, fixed rotation/variable speed, non-explosion proof/explosion proof, etc.